KS-20 CNC Sliding Head Swiss Machine

Machine may be shown with optional accessories.

KS-20 CNC Sliding Head Swiss Machine is a compact designed machine that integrates multiple tool slides with the main spindle and the sub-spindle. Complicated small parts applications can be quickly accomplished in one easy setup.

- 0.79" (20 mm) maximum turning diameter

- 8.07" (205 mm) maximum turning length

- Sliding head design

- Rotary guide bushing to increase stability when machining long work piece

- Main and sub-spindle feature C-axis functions

- Direct drive spindle

- 4 sets of tool slides

Features

VICTOR KS-20 Sliding Head CNC Swiss Machine

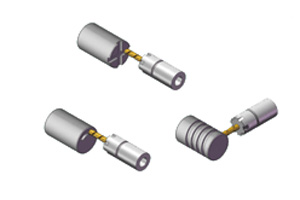

Direct Drive Spindle

- Spindle speed range from 500 ~ 10,000 rpm.

- The high speed direct-drive spindle permits full power transmission without backlash problem.

C-axis Contouring Function

- Indexing accuracy for main and sub-spindle is 0.001° which provides highly accurate contour machining.

C-axis Contour Machining

- Both main and sub-spindle feature C-axis functions for contour machining.

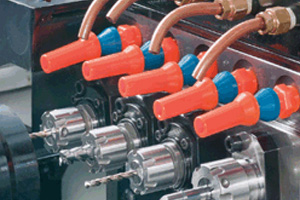

Rotary Guide Bushing

- Rotary guide bushing in the sliding head design assures stability, machining accuracy and high quality surface finish, especially when machining long workpiece.

- The sliding tool structure features no guide bushing design which minimizes material remnant to save cost.

Automatic Bar Feeder (Optional)

- Machine that is equipped with an optional automatic bar feeder allows fully automation operations to increase productivity and efficiency.

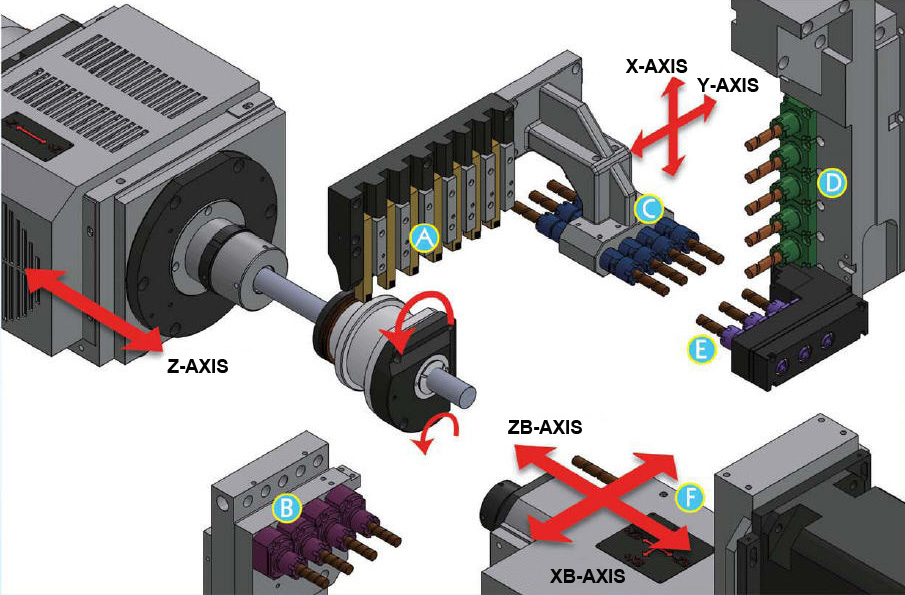

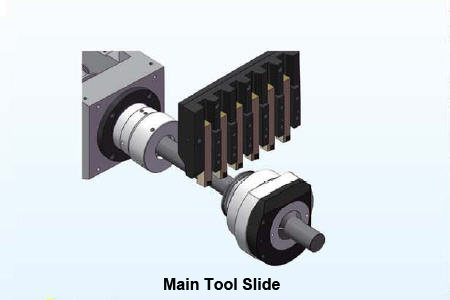

A

- The main tool slide can be mounted with 7 O.D. cutting tools.

- 12 x 12 mm tool shank size.

- Applicable for turning outside diameter of workpiece and cutting-off operations.

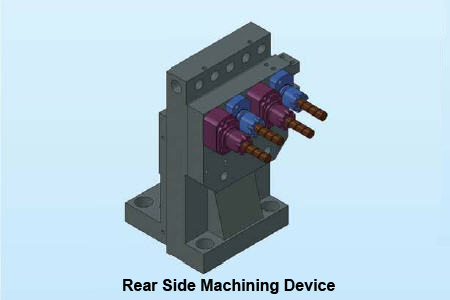

B

- The rear side machining device is used with the sub-spindle to perform rear side machining on workpiece.

- Machining device capacity: 4 cutting tools, all can be fitted with powered tools.

- 2 powered tools and 2 fixed tools as machine standard.

- Applicable for turning, drilling and tapping operations.

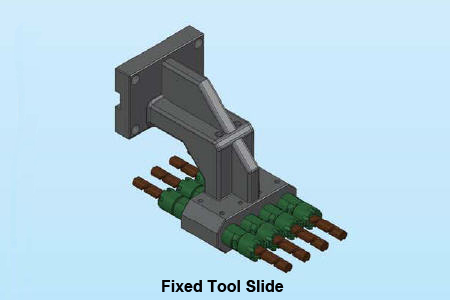

C

- The fixed tool slide is suitable for inside diameter machining.

- Applicable for drilling and tapping operations.

- Accommodates 4 fixed cutting tools.

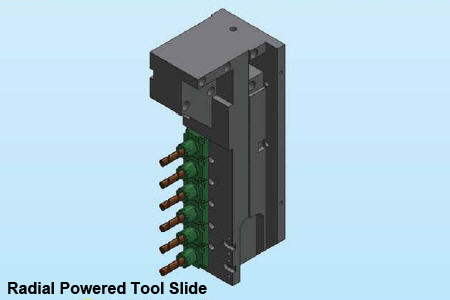

D

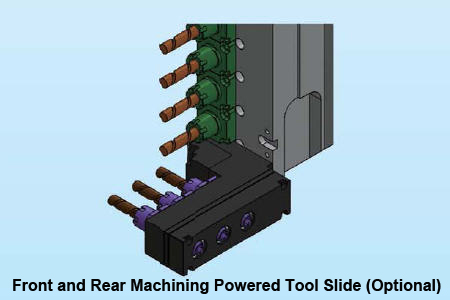

- The side milling device is applicable for side milling, drilling and tapping operations.

- Standard mount with 6 cutting tools.

- Optional mount with 4 cutting tools and a powered tool slide for front and rear machining.

- All powered tools are driven by servo motor.

E

- The tool slide is applicable for side milling, drilling and tapping operations.

- All powered tools are driven by servo motor.

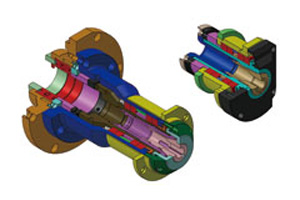

F

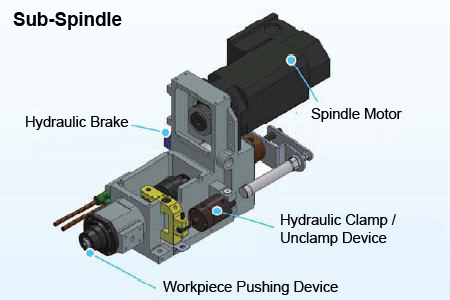

- The sub-spindle is used with a rear machining device to allow simultaneous machining on the rear side of workpiece.

- It features C-axis functions for contour machining.

- 8,000 rpm standard sub-spindle speed.

Accessories

STANDARD ACCESSORIES:

- Spindle motor

- C-axis function on main spindle

- Main spindle brake

- Sub-spindle

- Coolant pump

- High pressure cooling system 1.5 MPA

- Coolant tank

- Coolant level sensor

- Parts detector

- Parts catcher

- Parts conveyor

- Radial powered tools x 4

- Drilling spindle (ER16 x 2)

- Rear side machining tools for sub-spindle (powered tools x 2 / standard tools x 2)

OPTIONAL ACCESSORIES:

- Oil mist collector

- Automatic bar feeder

- Chip conveyor

- Chip bucket

- Coolant flow detector

- 440V transformer

Specifications

| MACHINE | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model: | KS-20 | ||||||||

| Type: | CNC Sliding Head Swiss Lathe | ||||||||

| CNC controller: | Fanuc Oi-TD | ||||||||

| CAPACITY | |||||||||

| Max. turning diameter: | 0.79" | ||||||||

| Max. turning length in one clamp/unclamp: | 8.07" | ||||||||

| O.D. TOOLS | |||||||||

| Number of tools: | 7 | ||||||||

| Size of tool: | 0.47" | ||||||||

| I.D. TOOLS | |||||||||

| Number of tools: | 4 | ||||||||

| Collet specification: | ER16 x 4 | ||||||||

| Max. drilling capacity: | 0.39" | ||||||||

| Max. tapping capacity: | M8 x P1.25 | ||||||||

| SIDE MILLING POWERED TOOLS | |||||||||

| Number of tools: | 6 ~ 10 (including optional tools) | ||||||||

| Max. speed: | 8,000 rpm | ||||||||

| Servo motor: | 1.6 HP | ||||||||

| Collet specification: | ER16 | ||||||||

| Max. drilling capacity: | 0.31" | ||||||||

| Max. tapping capacity: | M6 x P1.0 | ||||||||

| Max. end milling capacity: | 0.39" | ||||||||

| MAIN SPINDLE | |||||||||

| Max. speed: | 10,000 rpm | ||||||||

| Motor: | 3 HP / 5 HP | ||||||||

| Min. indexing unit: | 0.001° | ||||||||

| FEEDRATE | |||||||||

| Rapid traverse: | 945 ipm | ||||||||

| BACK SIDE MACHINING CAPACITY | |||||||||

| Max. clamping diameter: | 0.79" | ||||||||

| Max. length of front pick: | 3.15" | ||||||||

| Max. emerged length: | 1.18" | ||||||||

| BACK SIDE OF MACHINING TOOLS | |||||||||

| Number of tools: | 4 | ||||||||

| Max. drilling capacity (fixed tools): | 0.31" | ||||||||

| Max. drilling capacity (powered tools): | 0.20" | ||||||||

| Max. tapping capacity (fixed tools): | M8 x P1.25 | ||||||||

| Max. tapping capacity (powered tools): | M4 x P0.7 | ||||||||

| SUB-SPINDLE | |||||||||

| Max. speed: | 8,000 rpm | ||||||||

| Motor: | 2 HP / 3 HP | ||||||||

| Min. indexing unit: | 0.001° | ||||||||

| COOLANT | |||||||||

| Coolant capacity: | 210L | ||||||||

| WEIGHT & DIMENSIONS | |||||||||

| Center height: | 41.73" | ||||||||

| Machine size: | 112" x 68" x 83" | ||||||||

| Weight: | 7,716 lb. | ||||||||

* Design and specifications are subject to change without notice.

Machine may be shown with optional accessories